A.The magnetic pump works by.

The magnet pairs (n is an even number) are arranged and assembled on the inner and outer magnetic rotors of the magnetic actuator according to the law, so that the magnet parts are mutually formed into a fully coupled magnetic force system.The magnetic energy of the magnetic system is the lowest when the internal and external magnetic poles are opposite, i.e., the displacement angle Φ and 0 between the two magnetic poles, and the maximum is when the magnetic pole is rotated to the same pole, i.e., the displacement angle Φ and 2 π / n between the two magnetic poles.After removing the external force, because the magnetic poles of the magnetic system repel each other, the magnetic force will restore the magnet to the state of the lowest magnetic energy.The magnet then generates motion, which drives the magnetic rotor to rotate.

B.Selection step.

The status of magnetic pump production and magnetic materials, sliding bearing development, in order to ensure the quality of the project, in the selection of magnetic pump can refer to the following steps.

1. When the power of the pump is less than 10KW, select the magnetic pump to ensure the effect.

2. When the axial power of the pump is greater than 10KW or the medium temperature is higher than 100C, the domestic magnetic pump should be treated carefully, the material of magnetic steel and the structure of bearing material should be limited, and the shielded pump should be selected if necessary.

3. At present, the domestic magnetic pump manufacturers are generally medium and small factories, the development and research means are relatively weak.Generally speaking, it is not suitable to entrust the manufacturer to research or develop the pumps beyond the parameters of the products in order to ensure the quality and progress of the project.The main domestic magnetic pump manufacturers and their products are listed in Table 1-1.

4. The quality of magnetic steel material is related to the service life, reliability and price of the pump. When ordering, the magnetic steel material, the supplier and its performance index should be made clear.The material and life of the sliding bearing should also be defined.

Operation cautions.

1. Preventing particles from entering.

(1) ferromagnetic impurities and particles shall not be allowed to enter the magnetic drive and bearing friction pair.

(2) after conveying the medium which is easy to crystallize or precipitate, flush in time (pour water into the pump cavity after stopping the pump, discharge clean after running 1min), the common problems about the fire pump in our country, in order to guarantee the service life of the sliding bearing.

(3) when conveying the medium containing solid particles, it should be filtered at the inlet of the flow pipe of the ZCQ type self-priming magnetic drive pump.

2. Prevention of demagnetization.

(1) the magnetic moment can not be designed to be too small.

(2) it should be operated under the specified temperature condition, and the medium temperature exceeding the standard is strictly prohibited.The platinum resistance temperature sensor can be installed on the outer surface of the magnetic pump isolating sleeve to detect the temperature rise in the annular gap region so as to give an alarm or stop the machine when the temperature exceeds the limit.

3. Prevention of dry friction.

(1) No idling is allowed.

(2) medium extraction is strictly prohibited.

(3) when the outlet valve is closed, the pump shall not operate continuously for more than 2 minutes in case the magnetic actuator overheats and fails.

C.Compared with centrifugal pumps with mechanical or packing seals, magnetic pumps have the following characteristics.

1. The shaft of the pump is changed from dynamic seal to closed static seal, and the leakage of medium is avoided completely.

2. Without independent lubrication and cooling water, the energy consumption is reduced.

3. From coupling drive to synchronous drive, there is no contact and friction.The utility model has the advantages of low power consumption, high efficiency, and the damping and damping effect, which reduces the influence of the motor vibration on the pump and the influence of the cavitation vibration on the motor when the pump is subjected to cavitation vibration.

4. When overloaded, the inner and outer magnetic rotors are relatively slippage, which can protect the motor and pump.

D.Application of magnetic pump.

Magnetic pumps are widely used in petroleum, chemical, pharmaceutical, electroplating, environmental protection, water treatment, film and television development, national defense and other departments to pump and deliver flammable, explosive, toxic and valuable liquids.It is an ideal pump for creating leak-free and pollution-free lamination workshop and lamination factory.

Related reading:Stainless Steel Magnetic Pump,Corrosion Resistant Stainless Steel Pump

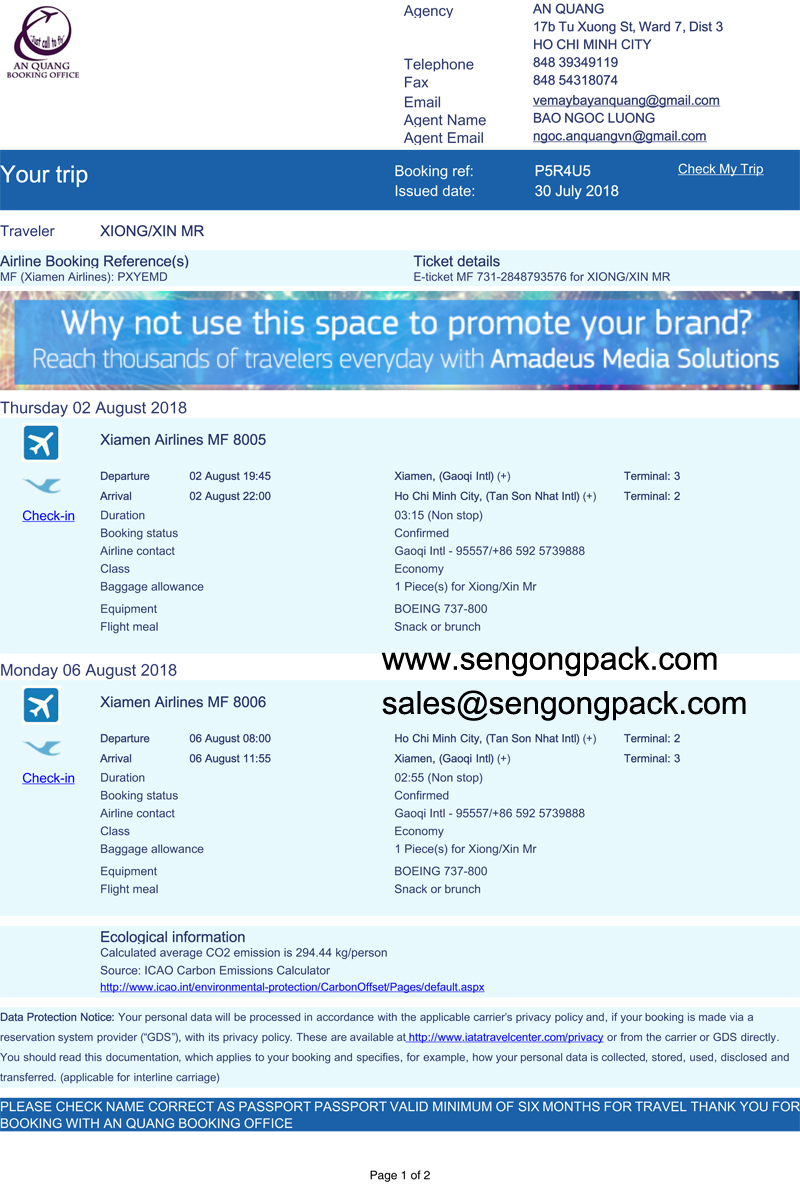

Our technician went to Vietnam country to service local client’s Tea Bag Packing Machine on 2nd,Aug,

Which named C13 Double Chamber Tea Bag Packing Machine,more details,welcome visit

company website.

Last week this client tell us he need service on site, some wrong with his machine.

Our company immediately arrange technician went to Vietnam.

Our technician found some machine parts are damage, and sensor also have malfunction. Machine begin normal operation after repair and replace some parts & sensor.

Now technician still in Vietnam to observed machine, also taught client how to right operate way, show some right way of maintain machine .

Everything is smoothly,finally Vietnam clients are satisfied with our after-sales service.

And hope this Vietnam tea business is blooming day by day!

Vietnam schedule

Service on client's work room

AdBlue Aqueous urea solution is alkaline with feature of non-toxic , non-pollutiing and non-flammable.

AdBlue Aqueous urea solution has special requirements for storage materials and storage conditions ,because of its alkaline characteristics .

(1) The effect of storage temperature on AdBlue DEF:

AdBlue requires a storage temperature of about -5 to 25 ℃, it should be avoid sunlight and high temperature. And different storage temperatures with different the shelf life .

The shelf life of AdBlue at different temperatures is as follows :

|

Storage Temperature(℃) |

Shelf life (Month) |

|

≤10 |

36 |

|

≤25 |

18 |

|

≤30 |

12 |

|

≤35 |

6 |

|

>35 |

Test before use |

It should be sealed immediately and not be used again if there is a strong smell of ammonia when opening the sealing cover of the storage tank, it can be used after passing the relevant instrument test immediately.

(2) The storage container and filling equipment of AdBlue ;

AdBlue DEF will react with some materials, such as copper, iron, aluminum and so on. it will cause the deterioration if it is installed in the pot or the filling equipments of these materials, thus affecting the performance of SCR. So it have to use special equipment for filling AdBlue. In addition, AdBlue will crystallize at low temperature and its volume will expand by about 7%. Therefore, the storage volume of AdBlue should be kept at about 90%.

(3)The storage and use environment of AdBlue should be cleaned.

In the process of using urea solution, we should try our best to avoid impurities from entering the solution and urea tanks. Generally, AdBlue have special tubes when refilling.

Heavy goods vehicles – trucks, coaches and buses have been using SCR technology and AdBlue since 2004. For example, Mercedes and Volkswagen.

The latest Euro VI emissions regulations from the European Commission has really driven an explosion in SCR technology from the passenger car perspective in Europe. The Euro VI regs introduced in 2014/15 demanded nitrogen oxides emissions should be reduced by a whopping 56% compared to Euro V levels. For most diesel engines over 1.6L in capacity, AdBlue and SCR technology has been the only means to achieve this. So most new diesel engines over that size will feature an AdBlue tank from now on.

a. After the Fluorine Plastic Centrifugal Pump stops working, should close the pump the population valve, after waits for the pump to cool down then in turn closes the auxiliary system valve.

b.High Temperature Magnetic Pumpshutdown should be in accordance with the provisions of the equipment technical documents, after the shutdown should be every deviation of 20 30min turning half a circle, until the pump body temperature down to 50 ℃ so far.

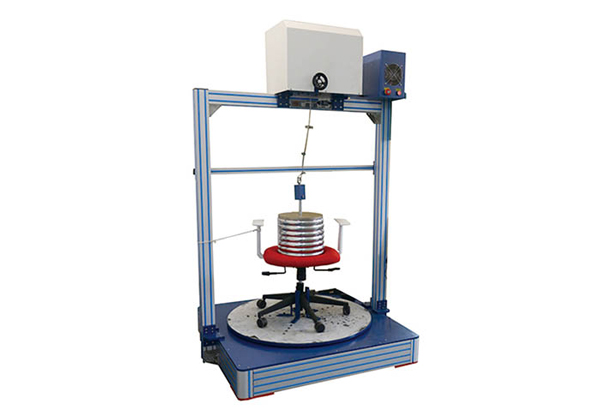

Only High quality swivel chair can withstand three test

QB/T2280-2016 Abrasion and Fatigue Test—Standard QB/T2280-2016

Under the load of 113kg, record a reciprocating cycle as one time and do reciprocating motion of the stroke.at least 762mm. whole course of one reciprocating cycle motion for 762mm stroke is more than 1.5m. The test of crossed obstacles for two thousand times and doing reciprocating cycles 98,000 times under obstacle-free conditions, totally 100,000 times for reciprocating motion of 762mm stroke, are equivalent to carrying 113kg of heavy objects and trudged more than 150 kilometers, but five casters of chair without any damage!

Impact Test-Standard QB/T2280-2016

Adjust the caster to the most vulnerable state and throwing 120kg sandbag to seat surface from the height of 152mm for 2 times. Then reduce the impact weight to 57kg, impact height to 30mm,repeated impact for 100,000 times. The casters are still very strong under 100,000 times impact test!

(Chair Swivel and Castors Durability Testing Machine)

Drop Test-Standard QB/T2280-2016

Lift the chair to a height of 200mm, the angle between the chair legs and the ground is 10±2°, then doing free fall for 10 times but the leg of the chair must not have any damage or defects for using.

(Caster and Base Durability Testing machine)

GESTER offers a number of furniture testing equipment to perform safety tests for office furniture, mattresses, suitcases as well as indoor/outdoor desks and chairs, thus evaluating their stability, durability, tensile strength, drop resistance, impact resistance, mechanical structure and other properties.

Carbide Rotary Burr is used for cutting, shaping, grinding and for the removal of sharp edges, burrs and excess material (deburring)

Carbide burrs are widely used for metalwork, tool making, engineering, model engineering, wood carving, jewellery making, welding, chamferring, casting, deburring, grinding, cylinder head porting and sculpting. And are used in the aerospace, automotive, dental, metal sculpting.

Choosing a good woodworking tool is especially important for wood processing, especially in complex furniture processing.

1. First, you need to understand the equipment management and quality inspection of the manufacturer. The equipment used for production, the strictness of management and quality inspection have a great influence on the wood router bit.

2. Check the appearance of wood router bit. observe whether the appearance of the woodworking knives is flawed, whether there is a small gap in the cutting edge of the woodworking knives, whether the knives of the woodworking knives are smooth, whether there are multiple faces and whether there are blunt edges at the cutting edges.

3.Measure the accuracy of the size of woodworking tools. Test the inner hole, size, outer diameter, shank diameter, etc.

4. Check the smoothness of the edge of the wood router bit.

220V Single-phase / 380V Three-phase U2 Universal Cutter Grinder

Universal Cutter Grinder is made up by main unit, wheel, spindle, drives, micro-feed and the grinding wheel dresser, knife the composition, structure, novel, modeling beautiful, high precision, good performance, easy to use, easy maintenance, applicable: computer engraving machine,engraving machine and high-speed rotary die knife cone head, edge grinding, and milling cutter blade cutting edge, grinding angles accurately. Universal Grinder is equipped with more advanced type of sharpener.

Reference News Network reported on October 8, Japanese media said that the global demand for industrial robots was driven by China. According to the International Federation of Robotics (IFR), Chinese sales in 2017 increased by 58%, setting a record of 138,000 units and accounting for more than 30% of the world. The labor shortage and the support policies of the Chinese government have played a catalytic role. China is setting off an unprecedented robot boom.

According to the report on October 8th by the Nihon Keizai Shimbun, according to the survey by Factory Network Asia, the total market share of Chinese local robot companies such as Shanghai Xinshida Robot (STEP) that owns ADTECH is 31.7% as of 2017. Compared with only 26.2% in 2013, it has continued to rise slightly. However, the report also pointed out that in the field of industrial robots in the world, Japanese FANUC and Yaskawa Electric, Swiss ABB and the German KUKA acquired by China Midea Group is considered the world's top four. In China, overseas companies account for nearly 70% of the remaining. In the field of smart phones and home appliances, Chinese companies have surpassed Japanese companies in a short period of time, but there are still gaps in the field of robotics, including technical strength.

According to the report, in China, which is the largest market for industrial robots, local companies are gradually gaining strength. In related fields, the market share of local Chinese companies has exceeded 30% in 2017 and is slowly catching up with Japanese and European companies. What is the Chinese position as the "world's factory" in the field of robotics that influences international competitiveness of the manufacturing sector. "Japan Economic News" interviewed the heads of the two robot companies in Guangdong, China, and asked about the issues and prospects of Chinanese industrial production.

Through electronics factory tempering technology

Adtech is the largest manufacturer of horizontal multi-joint robots (SCARA Robots) for electronic product assembly. Mr. Zeng Yiqiang, chairman of the company, pointed out that if you accumulate experience in electronic products factories such as personal computers, it is possible to catch up with Japan and Europe.

Reporter: In the field of robotics, Japanese and European companies are leading. What do you think for this?

Mr. Zeng Yiqiang: In terms of the durability of SCARA robots, ADTECH is temporarily behind Japanese companies such as Yamaha Engine and Seiko Epson. What we are better at is the ability to respond to meticulous needs. We have a dedicated team dedicated to tightening screws and welding processes and can be dispatched to our customers' factories. No overseas company can deal with it in such detail.

Reporter: How to narrow the quality gap with Japanese and European products?

Mr. Zeng Yiqiang: From the historical point of view, the overseas robot industry generally improves its strength by keeping pace with the country's automobile industry. Nowadays, the demand for electronic products factories such as personal computers and smart phones has also become the driving force for the development of the robot industry.

The electronics factory is concentrated in China. Companies like ADTECH can beat overseas companies if they can meet new demands and focus on R&D.

Labor costs rise to boost automation demand

The head of a company responsible for the development of robots in Dongguan pointed out that in order to cope with the increase in labor costs, the automation of the factory is indispensable.

Reporter: How many robots is running in the company?

Responsible person: There are 300~400 units, which will increase to 1000 units during the year. In order to use in the company factory, we started to develop robots in 2013 and started production and introduction in 2015.

Reporter: What is the reason for accelerating R&D and introduction of robots?

Responsible person: Because factories are hard to recruit workers, and labor costs are rising. The current labor costs have almost doubled than the costs in 2008. The number of employees is about 10,000, but when the delivery time of the circuit board of the new smartphone is approaching, there will be a shortage of about 3,000 people. These need to be offset by robot-based automation.

درباره این سایت